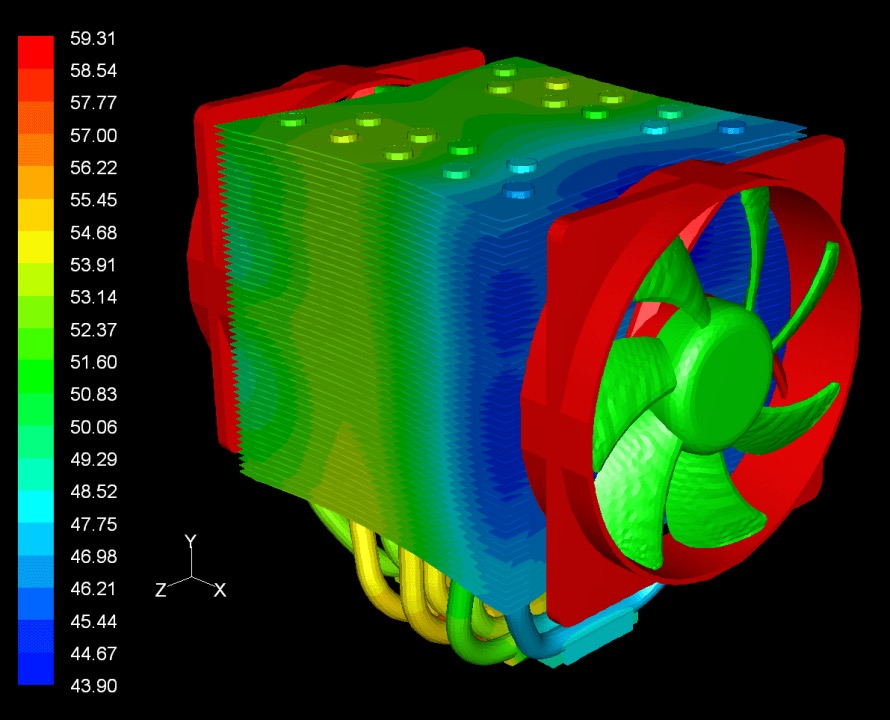

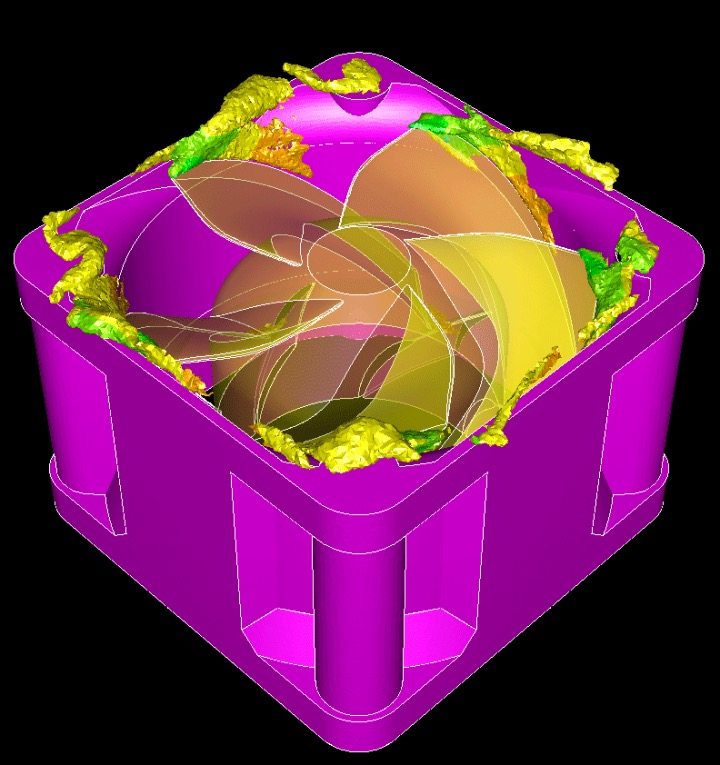

(2) Forced air cooling: Forced air cooling that uses dedicated or system-level fans to realize convection under the conditions with special air flow velocity requirements. A configuration with coolers, high-density fin assemblies, and heat exchangers can generate an environment with counter flows or intercross air flows so as to speed up removing the heat and enhance the cooling efficiency. Force air cooling techniques can also work together with cooling techniques with phase-changing fluid which is typically contained inside a sealed copper heat pipe. The cooling effect is realized by the rapid alternation of liquid evaporation and condensation at a lower boiling point. When a product has a higher density or when the space is confined, the cooling capacity of a heat sink can be enhanced when heat pipes are integrated into the design.

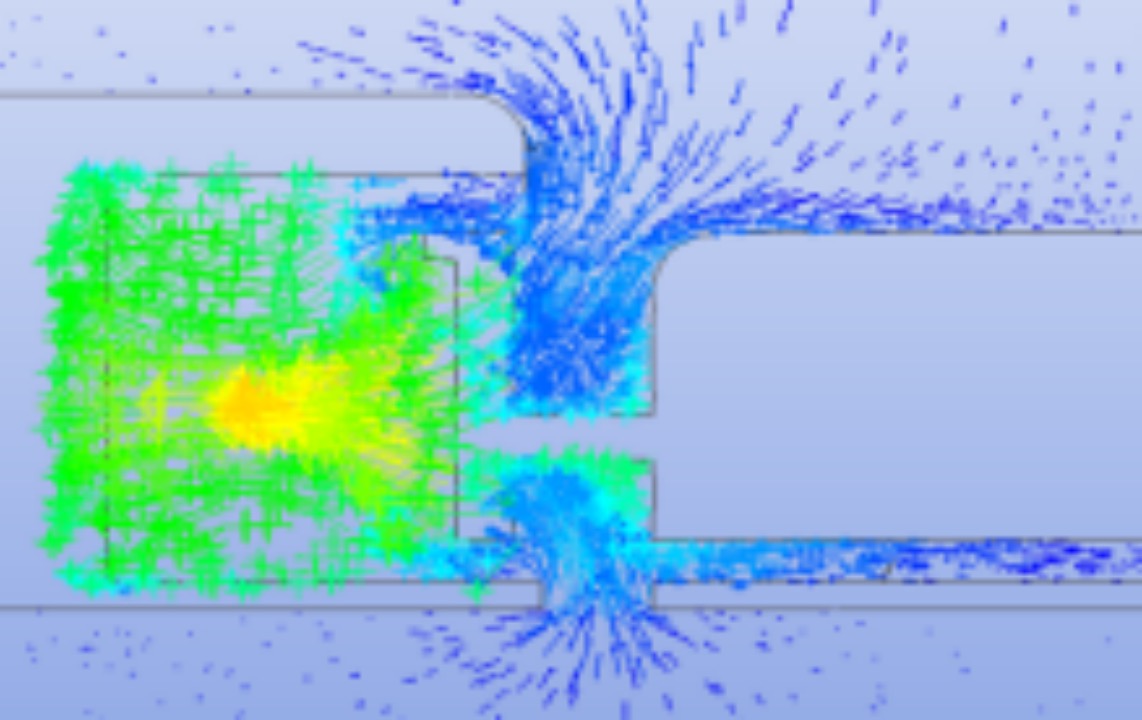

(3) Liquid cooling technology: Liquid cooling applications deal with liquid cooling plates (also called water cooling plate) that are installed onto heat sources. It works together with heat exchangers and pumps to dissipate heat by the circulation of liquid. Under typical conditions, liquid cooling applications are used in an environment with higher thermal energy density that either forced convective cooling or phase change system are not able to meet the required cooling effect. In recent years, Winshare Thermal strengthened our development of liquid-cooling technology and especially the continuous renovations of production techniques for water-cooling products. This allows us to produce more robust cold plates by welding, greatly reduce the failures such as leaks on the cold plates, and enhance the reliability of the cooling capacity of cold plates.

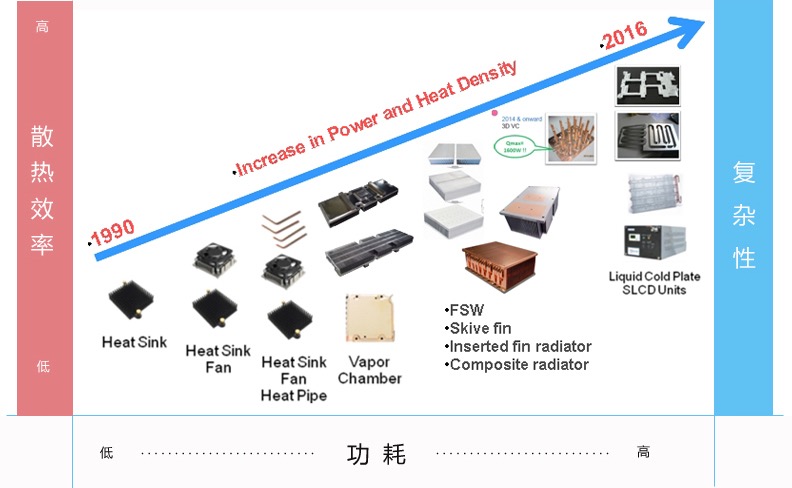

During the period of 1990 to 2016, new product developments in various fields moved toward the direction of concentrated heat sources with higher power and higher density. This trend applied more stringent requirements on the cooling capacity and special limitation on a cooling system. It has been more obvious since 2010 when the density of industrial products increased rapidly with the renovation of high-density cooling technologies and solutions. In the last couple of years, skived fin, heat pipe thermal module, 3D/VC applications, and micro-channel liquid cooling have become the mainstream cooling techniques.

1、Natural cooling

2、Forced air cooling

3、Surface technology

三、Thermal management solutions

Improving MTBG (Mean Time Between Failures)

Our professional thermal management engineers can provide the most advanced and most efficient cooling solutions under the consummate customization process and system. We can save unnecessary costs on the design resources, thermal modeling, and testing equipment. From a design concept to its production, Yijie Group Thermal's R&D department can always provide you with cooling technical support at any moment.